Laser cutting is by far the most precise and the most economic cutting technique for the dimensions and thickness we work with. Laser cutting is also time efficient and leaves minimal spillage.

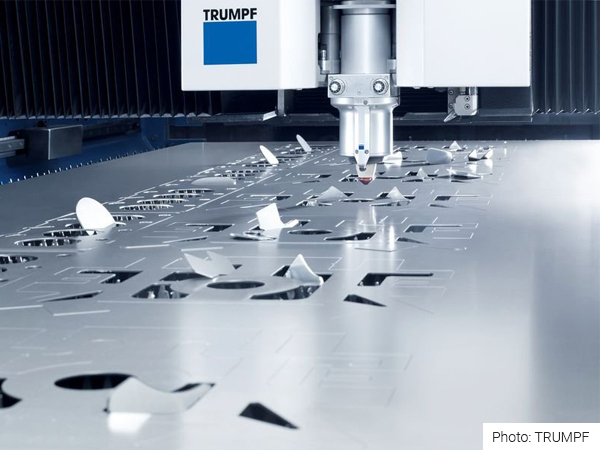

Our 2D Laser machines:

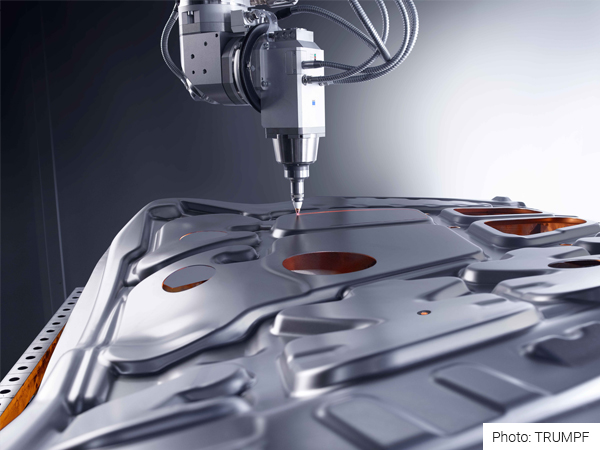

Our 3D machines are prepared both for cutting and wielding with CO² and we are able to work with the most common dimensions and materials together with a rotary table of Ø2000 mm.

Our 3D Laser machines:

Laser cutting requires no punching tools or other mechanical preparations. It both reduces entry costs, enables rapid production and creates the opportunity to produce small series at a competitive price. The precision and quality are extremely high and even as the cut is done automatically. The laser technology manages figures and shapes that one can never achieve with any other method and offers great possibilities both in terms of design and material choice.

We have three 2D flat laser machines and two 3D laser machines. We laser cut in a variety of steels, stainless steels, aluminum and titanium grades, various Ni- and Co alloys. The 2D laser machines have a working area of 3000 x 1500 mm and cut up to a maximum thickness of 25 mm stainless and carbon steel with precision within one tenth of a millimeter. For aluminum it can handle thicknesses up to 12 mm.

By equipping one of our 3D laser machines with a large rotating table, we have created the possibility of processing even in larger dimensions.