Our operation shall always aim to exceed our customers expectations and we shall in all cases fulfill all the obligations stated by law, customer contracts and by industry standards.

With the guidance of our quality and environmental management systems, Trestad Laser shall secure a high total quality and prevent pollution and waste of resources.

Using good communication, continuous education and cooperation, we will create a working place that achieves top-of-the-line quality products and an enjoyable workplace.

AS9100D (Equivalent to EN 9100:2016)

ISO 9001:2015

ISO 3834-2:2021

ISO 14001:2015

DIN-2303

EN-1090-1:2009+A1:2011

EXC1 EXC2 EXC3

Our concept is to produce a complete product. We achieve this with our own machinery and techniques all the way from metal blanks to finished product.

We are constantly working to improve the flow of our production and to keep delivery times down for our customers.

We work with products for which the demand for precision, form stability and durability against high temperatures, pressure, chemical and mechanical wear are extremely high. Continuous improvements of both systems and processes are essential in order to secure high quality and good relationships with customers and suppliers over time. Our goal is to be our customers number one partner and to be a partner that always maintains high quality through the whole business process.

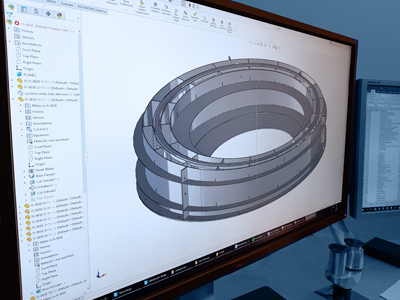

We work with products where the demands on precision, shape stability, resistance to high temperatures and pressure are extremely high. Therefore, the quality of our preparative work and production of blanks and fixtures is extremely important. Our designers use SolidWorks as their 3D design software.

Our ability to keep good relations with customers is the key to why our business has been so successful during the last decade. We care for the relationship we have with our customers and make sure that we deliver nothing but first class quality components that they require.

Trestad Laser has since our start in 1972 advanced from bending and simpler welding to advanced laser welding and laser cutting in 3D, as well as advanced press processing and fully automated welding.

We are currently certified by AS9100D (technically equivalent to EN 9100:2016), DIN-2303 and ISO 9001:2015 and weld certified by ISO 3834-2:2021. We are also environmentally certified by ISO 14001:2015 and EN-1090-1:2009+A1:2011.

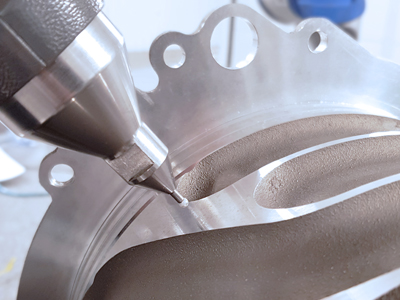

Our vertical machining center uses a high-precision spindle with heavy duty cutting power producing minimal heat distortion, allowing the machines to achieve high accuracy, high rigidity and high precision.

MoreLaser cutting is by far the most precise and the most economic cutting technique for the dimensions we work with. Laser cutting is also time efficient and leaves minimal spillage. We perform both 2D and 3D laser cutting.

MoreWe perform TIG, MIG/MAG, Plasma, Laser, resistance and distance welding in all materials such as Aluminum, Titan, Inconel, Hastelloy and many more. (Aluminum welding in this picture)

MoreWe perform manual and automated heat treatment processes up to 800°C that are well documented.

MoreAutomatic bender for advanced tube bending with automation, flexibility, ease of use and productivity on tubes up to 25 mm.

MoreOur complete combination of advanced automated machines give us the ability to perform high pressure and bend work in a great variety of dimensions.

MoreWe perform radiographic, pressure and liquid penetrant tests together with DEKRA Industrial AB. We also do visual inspection and dimensional controls.

More

2D Laser

peter.andersson@trestadlaser.se

3D Laser

max.andersson@trestadlaser.se

Quality / Environment

jimmy.johansson@trestadlaser.se

Production Manager

conny.kron@trestadlaser.se

Production Development

ulf.renholm@trestadlaser.se

5S Lean Production

pehr.wikstrom@trestadlaser.se

Order Preparation

birgitta.pettersson@trestadlaser.se

Order Preparation

johan.gustavsson@trestadlaser.se

Order Preparation

lene.alexandersen@trestadlaser.se

Order Preparation

mats.karlsson@trestadlaser.se

Order Preparation

mattias.karlsson@trestadlaser.se

Order Preparation

oscar.hillstrom@trestadlaser.se

Order Preparation

stefan.tallbo@trestadlaser.se

Fabrication

ulf.nilsson@trestadlaser.se

Sustainability

josefine.sundberg@trestadlaser.se

Document Controller

deija.cronholm@trestadlaser.se

Administration

maria.jensen@trestadlaser.se

Logistics

joel.guterstam@trestadlaser.se

IT Security & Development

ola.udd@trestadlaser.se

Faktorsgatan 3

461 37 Trollhättan

Sweden

+46 520 47 80 70

info@trestadlaser.se